Disassembling the original fence and marking new runner. First, you need to make sure the table is completely square and is at 90 degrees from the blade.

Make A Fence For Table Saw, So after cutting of accurate size of sheet assemble it in correct position. First step of making a table saw machine is make a table.

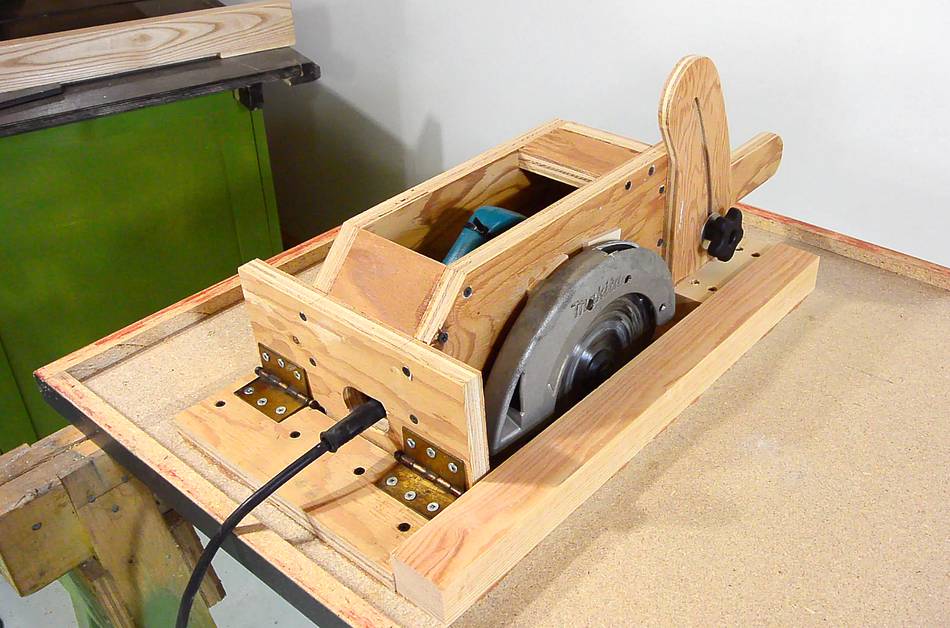

Here are necessary things you will need to make a table saw fence for the homemade table saw. This table saw fence does all this and keep saw dust from piling up in the front. You should always make sure that your fence is perpendicular to the saw, secure and not flexible, as there will be a lot of pressure when the material is placed in between the fence. Several pieces of square wood (0.7×0.9 inches) plywood blades;

This table saw fence does all this and keep saw dust from piling up in the front.

However, not latching at the back does not prove it to be any less sturdy. Make sure the material is adequately finished to prevent any wastage, The process is simple and extremely easy to follow. To achieve this level of accuracy and automation, the fence runs on single carriage sliding on two pieces of 20mm skf linear rails. You should always make sure that your fence is perpendicular to the saw, secure and not flexible, as there will be a lot of pressure when the material is placed in between the fence. A very strong diy table saw fence make 3 machines in 1 table part 4 fence author:

Source: thedailygardener.com

Source: thedailygardener.com

For this project, you would need aluminium, screws, t nuts, plywood, drills, hammers, table or hand saw, and some others. You can always just put it back to the same distance from the blade and get exactly the same width of cut. Turn on your saw and test run the fence with a piece of scrap wood. After this, cut.

Source: reddit.com

Source: reddit.com

After this, cut the wood and position it appropriately. Steps to make a table saw fence step 1: Several 50 mm wood screws; The list above will guide you in making your favorite selection. Turn on your saw and test run the fence with a piece of scrap wood.

Source: youtube.com

Source: youtube.com

This table saw fence does all this and keep saw dust from piling up in the front. Make sure at what saw size a particular fence will fit the best. You can always just put it back to the same distance from the blade and get exactly the same width of cut. This is an easy diy project when you.

Source: pinterest.com.au

Source: pinterest.com.au

Use four 25 millimeter screws to attach the fence to the slider top. First step of making a table saw machine is make a table. You can still make a fence for it with this super easy diy plan. You should always make sure that your fence is perpendicular to the saw, secure and not flexible, as there will be.

Source: ibuildit.ca

Source: ibuildit.ca

Make sure you get everything written here beforehand to save yourself extra time and effort. First, you need to make sure the table is completely square and is at 90 degrees from the blade. Several pieces of square wood (0.7×0.9 inches) plywood blades; Whichever is your dominant hand, you will want to place the fence on that side of the.

Source: thedailygardener.com

Source: thedailygardener.com

The easy to grasp video tutorial has all you would need to build your table saw fence for your homemade table saw. I have used 18mm thickness plywood sheet. This is an easy diy project when you follow these free. Turn on your saw and test run the fence with a piece of scrap wood. The table saw fence also.

Source: pinterest.com

Source: pinterest.com

Aluminum (preferably of the rectangular profile) wood screws (size: Making your own table saw fence is a great way to ensure it is parallel, accurate and most importantly, durable. Download free plans with dimensions (pdf) 3d model. Disassembling the original fence and marking new runner. Square scrap pieces of mdf are then screwed into the inside of the assembly to.

Source: woodhutt.com

Source: woodhutt.com

T2 fence to a craftsman table saw. The list above will guide you in making your favorite selection. Table saw workbench with custom fence [splitbrain.org] step 1: The plans were made for a table top that is 23 inches (584mm) from front to back, and if yours is bigger, you may want to make the fence parts longer to match..

Source: youtube.com

Source: youtube.com

Turn on your saw and test run the fence with a piece of scrap wood. For assembly use of long size screw and glue is necessary. The process is simple and extremely easy to follow. Make sure the material is adequately finished to prevent any wastage, The process is simple and extremely easy to follow.

Source: theselfsufficientliving.com

Source: theselfsufficientliving.com

First of all cutting accurate size of sheet for table, all the dimension are shown in the image. Turn on your saw and test run the fence with a piece of scrap wood. This table saw fence does all this and keep saw dust from piling up in the front. First step of making a table saw machine is make.

Source: bestconsumersreview.com

Source: bestconsumersreview.com

So, in this section, i’ll show you how to make a table saw fence. First, you need to make sure the table is completely square and is at 90 degrees from the blade. First of all cutting accurate size of sheet for table, all the dimension are shown in the image. Disassembling the original fence and marking new runner. Download.

Source: instructables.com

Source: instructables.com

Some table saws can work with fence size as small as 27 inches, while others require a lengthy fence of about 42 inches, latching only in front and can fit a table of any level. T2 fence to a craftsman table saw. First, you need to make sure the table is completely square and is at 90 degrees from the.

Source: lumberjocks.com

Source: lumberjocks.com

Turn on your saw and test run the fence with a piece of scrap wood. Moreover, you can also modify the structure of the old table saw with this craft. This table saw fence is different from the others, in that it is a diy table saw fence for a homemade table saw. Finally, use nuts and sturdy threaded rods.

Source: woodgears.ca

Source: woodgears.ca

Feather boards are like a pair of extra hands that can provide downward pressure on the work piece as it passes through the saw. The table saw fence also needs to be easy to adjust, lightweight, and easy to lock into place. To make it i used: To achieve this level of accuracy and automation, the fence runs on single.

Source: woodgears.ca

Source: woodgears.ca

Make sure you get everything written here beforehand to save yourself extra time and effort. This system works with any 2×3 biesemeyer style guide rail system. So after cutting of accurate size of sheet assemble it in correct position. Take measurements of the length of your table saw table and cut two boards of the same length from the materials.

Source: woodgears.ca

Source: woodgears.ca

In this way, it would be effortless for your to work on the saw. It is driven with a. After this, cut the wood and position it appropriately. Before doing any assembly, i cut out all of the parts. So the first thing i recommend as an attachment to the ultimate table saw fence are feather boards.

.jpg “How To Make A Table Saw Fence IBUILDIT.CA”) Source: ibuildit.ca

Aluminum (preferably of the rectangular profile) wood screws (size: Moreover, you can also modify the structure of the old table saw with this craft. Turn on your saw and test run the fence with a piece of scrap wood. After this, cut the wood and position it appropriately. First of all cutting accurate size of sheet for table, all the.

.jpg “How To Make A Table Saw Fence IBUILDIT.CA”) Source: ibuildit.ca

Finally, use nuts and sturdy threaded rods to build a solid lock for your table saw fence. Making your own table saw fence is a great way to ensure it is parallel, accurate and most importantly, durable. The whole point is to make your experience comfortable and easy. For assembly use of long size screw and glue is necessary. The.

Source: youtube.com

Source: youtube.com

Several 50 mm wood screws; For this project, you would need aluminium, screws, t nuts, plywood, drills, hammers, table or hand saw, and some others. Before doing any assembly, i cut out all of the parts. Take measurements of the length of your table saw table and cut two boards of the same length from the materials of your choice..

Source: theselfsufficientliving.com

Source: theselfsufficientliving.com

So, in this section, i’ll show you how to make a table saw fence. The list above will guide you in making your favorite selection. The easy to grasp video tutorial has all you would need to build your table saw fence for your homemade table saw. Before doing any assembly, i cut out all of the parts. Use a.

Source: youtube.com

Source: youtube.com

Several 50 mm wood screws; You will need the following materials to build your table saw fence: Make sure the material is adequately finished to prevent any wastage, Make sure at what saw size a particular fence will fit the best. Making your own table saw fence is a great way to ensure it is parallel, accurate and most importantly,.

Source: pinterest.com

Source: pinterest.com

The whole point is to make your experience comfortable and easy. After this, cut the wood and position it appropriately. Set up your table saw with dado blades to cut a 1/2 dado, 1/2 deep. Make a table saw fence for diy table saw. The easy to grasp video tutorial has all you would need to build your table saw.

Source: in.pinterest.com

Source: in.pinterest.com

Make sure at what saw size a particular fence will fit the best. Moreover, you can also modify the structure of the old table saw with this craft. The easy to grasp video tutorial has all you would need to build your table saw fence for your homemade table saw. First of all cutting accurate size of sheet for table,.

Source: youtube.com

Source: youtube.com

Set up your table saw with dado blades to cut a 1/2 dado, 1/2 deep. T2 fence to a craftsman table saw. I have used 18mm thickness plywood sheet. This is an easy diy project when you follow these free. Making sure you have everything you need before you start will ensure the building of your table saw fence goes.

Source: pinterest.com

Source: pinterest.com

The process is simple and extremely easy to follow. So after cutting of accurate size of sheet assemble it in correct position. All table saws need a fence that will help guide the wood for precise and safe cutting. In this way, it would be effortless for your to work on the saw. Make sure the material is adequately finished.